Ranger Electronic Initiation System

Safe.Simple.Smart.

The new Ranger by Dyno Nobel is the ultimate DigiShot® blast initiation system designed with safety and performance at its core.

Unique features such as end-of-line voltage validation, auto detonator detection, and flexible tagging maximize your productivity on the bench. The integrated RF antenna delivers the durability and reliability you need. Ranger helps you optimize your time on the bench and at the blast.

Ranger Brochure

Ranger Electronic Initiation System

Features

• Fast and Simple "tag by plan" deployment method

• Automatic check to ensure the correct number of detonators per channel

• Detonator energy monitoring right up to the point of blasting

• Autonomous detection and testing of detonators

• Programming speed is 6 times faster than existing systems

• Blaster wirelessly controlled through the multi-purpose CE4 Tagger

• Built in - long range antenna up to 1.86 miles (3km)

• Multi-purpose Ranger can be configured as a Bench of Base

• Twice the detonator capacity - 600 dets (300 dets per channel at 40m)

The Ranger has been completely redesigned for the open cut, quarry, civil and construction industry. It has been vastly improved from the DigiShot 300 predecessor, providing twice the detonator capacity, updated weatherproof enclosure with a built-in antenna for longer range RF up to 3km, which makes it more robust for quick and easy deployment.

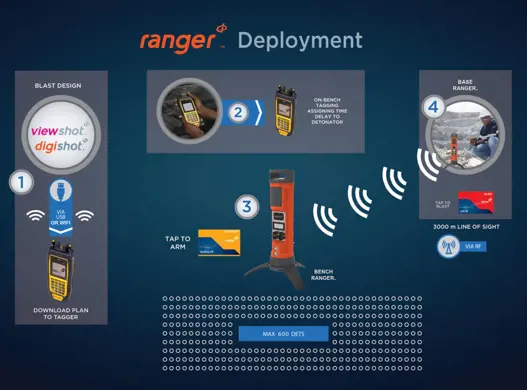

Ranger Deployment

Tagging is flexible with a capacity of 600 detonators. The Bench Ranger is designed with simplicity in mind but is a sophisticated piece of equipment with its auto-detonator detection the Bench Ranger will find every detonator connected to the surface wire tag or untagged (hook up and go).

The Ranger is also able to be fired remotely with a built-in antenna that is reliable on every blast. The Blast Cards ensures that the user is in total control of the blast pattern and ensures safe arming and firing of the blast pattern.

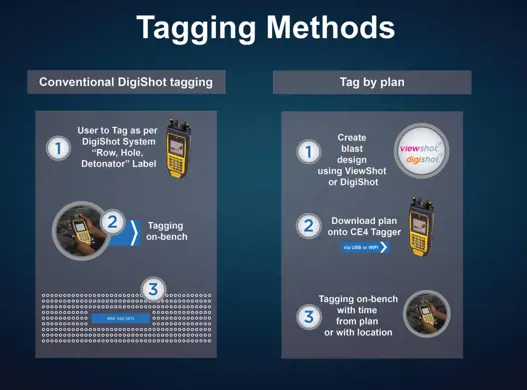

Tagging Methods

Our conventional “Row, Hole, Det” methodology is available for our current customers that appreciate the method with little to no training required. We also have the option to preplan/predesign a blast plan via our CE4 tagger or ViewShot blast application.

The design is then transferred to the CE4 tagger or activated on the CE4 tagger, the user will now only have to tag the det at the hole displayed with Location and delay. No additional step is needed, and all information is stored in the detonator itself.

Safe. Simple. Smart

Unique features such as end-of-line voltage validation, auto detonator detection, and flexible tagging maximize your productivity on the bench. The integrated RF antenna delivers the durability and reliability you need. Ranger helps you optimize your time on the bench and at the blast.