Drill/Blast Labor AssistImpala Canada Ltd.

Client: Impala Canada Ltd.

Site: Lac des Iles Mine

Project Elements: Create and issue production drilling and blasting designs

State and Country: Ontario, Canada

Commodity: Palladium

Project Year(s): 2022

Project Description: Due to a shortage of production planning staff available at Lac des Iles Mine, DynoConsult’s Eastern Canada team was requested for assistance. Over the course of five months, two Field Consultants performed as production planners, rotating in and out of the remote site every two weeks. Day-to-day operations required our Field Consultants to fulfill shift-by-shift requests, from operations and technical services, for drilling and blasting designs. Following weekly plans, the remainder of the time available to them was dedicated to creating full design packages. Since this mine is well established and uses a combination of underground mining methods, best practices and approved standards were confirmed and followed in the designing process.

Post-Blast Fume Investigation

Agnico Eagle Mines Ltd.

Client: Agnico Eagle Mines Ltd.

Site: Detour Lake Mine

Project Elements: Investigate causes of post-blast fumes

State and Country: Ontario, Canada

Commodity: Gold

Project Year(s): 2022

Project Description: After some high gas readings were measured following a blast at Detour Lake Mine, DynoConsult was requested to investigate some of the potential causes or contributors to the issue. In this case, the first step was to ensure Dyno Nobel’s emulsion was performing according to specifications. To do this, cup samples were taken to make sure the correct density of emulsion was being used, after which the velocity of detonation was measured.

The next step was to review the drilling patterns and timing sequences for any indication of possible causes of post-blast fumes. All blast recordings from the preceding three months were reviewed for any amount of visual NOx. For all blasts in which NOx was visible, DynoConsult requested the associated drill patterns and timing sequences for further examination. After concluding the investigation, the results were compressed into a presentation and given to mine personnel with associated recommendations to mitigate the risk of excessive gases in the future.

Blast Design Review and Approval by a Professional Engineer

Gateway Materials Ltd.

Client: Gateway Materials Ltd.

Site: Bedford Quarry

Project Elements: Review and approve all blast designs

State and Country: Nova Scotia, Canada

Commodity: Aggregate – quartzite and granite rock

Project Year(s): 2017-2021

Project Description: Following a site incident and a temporary quarry shutdown, a sites’ Code of practice was modified. The updated document requested that all blasts must be reviewed by a Professional Engineer before the loading process begins. Dyno Nobel was the explosive product supplier for the site and reached out to DynoConsult to review the blast designs and confirm that they are safe, acceptable and that they conform to the updated Code of practice. The sign-off process, done by a licensed Engineer, included the review of the design and all relevant information including the previous blasts, post-blast reports, seismograph vibration readings, videos, as well as the loading charts, stemming lengths, initiation sequence, borehole deviations and profiles, drilling logs and danger zone calculations.

The site was located at an approximate distance of 300 m from Bicentennial Highway and around 400 m from existing apartment buildings. Following a 5-year project, the site has successfully initiated up to 30 blasts per year without any incidents. DynoConsult’s expertise was very valuable to keep the site open by executing all blasts in a safe manner, according to best practices and by eliminating any potential risks such as flyrock projections.

Engineer's Design and Supervision of Loading and Shooting Services in Outcrop 3

New Gold

Client: New Gold

Site: Rainy River Gold mine

Project Elements: Design, coordinate and supervise drilling, loading-shooting and mucking operations

State and Country: Ontario, Canada

Commodity: Aggregate for building roads, dikes and crusher pad

Project Year(s): 2017

Project Description: A Northwestern Ontario gold mine requested complete blast loading and shooting services to excavate rock at their adjacent quarry to produce building material for roads, dikes and crusher pad. The mine requested 1 500 000 m3 or 4.35M tonnes of granite rock to be excavated within a 3.5 months’ timeframe for their building needs. This work required to have a drill and blast engineer on site to prepare blast designs, sequence the blasts, coordinate stripping, drilling and mucking crews as well as supervise loading operations and attend meetings with client. Dyno Nobel was selected to provide all explosive related handling and storing services but needed a Professional Engineer licenced in the province of Ontario to complete the design and coordination work. DynoConsult was approached to provide 2 site engineers that would work on a 14-14-day fly-in fly-out rotation to complete this task.

Early March 2017 DynoConsult was on site to start to organize major quarry operations of subcontractors. This included to provide guidance for excavation/stripping crew to clear necessary blast sites from overburden, construct access roads and manage water. Drill crew needed to be directed where to drill holes with respective depths; four drills were working 24/7 on this project and were asked not to stop at any time. Blast designs included large volume shots to keep mucking crew busy. Apart from these obligations, DynoConsult engineers managed explosive orders and loading crews.

General blast parameters were provided but changes were allowed. Various techniques and trials were conducted to optimize all operations, but the biggest focus was made on blasting aspect of this project. Due to some mine delays, the project was successfully completed in 6 months with great results and no incidents or time lost for any crew. In all, 21 blasts were designed for a total volume of 1 515 900 m3 or 4.4 M tonnes.

Georgia Technical Support

Martin Marietta

Client: Martin Marietta

Sites: Red Oak, Newton, Paulding, Morgan, SixMile, Lithonia

Project Elements: Data Collection, Data Processing

State and Country: Georgia, USA

Commodity: Crushed Stone

Project Year(s): 2

Project Description: Dyno Nobel provided Bethany as technical support to the Martin Marietta Operations in the greater Atlanta area. Many shots require 3D profiling or boretraking, so these were done with drone or Quarryman and cabled boretrak to provide quality information to the blasters, and improve shot quality. Additionally, fragmentation studies and dig-ability time studies were done to analyze shot performance at Newton Quarry. These services improved shot quality and helped with shot performance analysis when making changes to the blast patterns.

Quarry Blasting at 57m from Homes without Blast Mats

Demix Agrégats

Client: Demix Agrégats, div. of CRH Canada Group inc.

Site: St-François Quarry

Project Elements: Risk analysis, blast design and execution according to strict environmental requirements

State and Country: Quebec, Canada

Commodity: Limestone aggregate

Project Year(s): 2017

Project Description: DynoConsult was approached by a local quarry where Dyno Nobel was the explosive provider to evaluate, design and execute in a safe manner the excavation of ±230 000 tonnes of rock at distances of 40 to 57 m from adjacent buildings. Since the site presented some exceptional challenges, a higher level of expertise and engineering skills was required to safely extract the rock. Site constraints included the respect of environmental requirements, zero flyrock tolerance, avoid the use of blast mats, provide rock fragmentation similar to current production and limit the amount of oversize.

As this area was not mined in recent years, only limited data was available of previous designs. DynoConsult used the empirical formulas to prepare a new design and employed best blasting techniques to safely excavate the required volume. Because of the proximity of the buildings and limited knowledge of the site, it was determined that the area would need to be split into 3 different blasts. All personnel in the blast area was evacuated to prevent any potential injuries. Based on 1st and then 2nd blast, different blast parameters were adjusted to achieve good blast results: line drilling, stemming, bulk and packaged products, decks, shock resistant boosters, electronic initiation system, etc.

The work spanned across 8 months and it included an exhaustive preparation period followed by the loading and initiation process and included a post-blast analysis to better prepare the subsequent blasts. Many site visits, calculations and counter-verifications were done to avoid any surprises. Following the 3 blasts, mucking was completed using the same equipment within the same timeframes. Although oversize was not quantified, it could be estimated that the amount was less than 2%. All occupants in the immediate blast area were evacuated and traffic stopped for added safety. Post-blast analysis of videos and immediate site area did not show any signs of flyrock. As an additional verification, an inspection of all adjacent buildings was completed, and it was concluded that no rock left the predetermined blast zone. All vibration and air-overpressure limits were respected.

Savage Stone Fragmentation Analysis

SW Barricks

Client: SW Barricks

Site: Savage Stone

Project Elements: Fragmentation Analysis

State and Country: Maryland, USA

Commodity: Aggregate

Project Year(s): 2020

Project Description: The customer was interested in optimizing fragmentation in the muckpile. They had two goals, the first was to minimize oversize, (material greater than 48”). The second was to maximize fines, (material below 6”). Everything below 6” bypasses the jaw crusher, which increases throughput and saves on energy costs. WipFrag software was used to determine particle size distribution. For each shot, around 10 representative photos were taken of the interior of the muckpile, using a scale. Additionally, drone photos of the top of the muckpile were used to determine oversize. The photos were analysed and a cumulative particle size distribution for the shot was determined. This information provided quantitative measurements to make data driven decisions regarding pattern selection and stemming heights.

Underground Stope Analyses

Carmeuse

Client: Carmeuse

Site: Luttrell

Project Elements: Data Processing

State and Country: Tennessee, USA

Commodity: Limestone

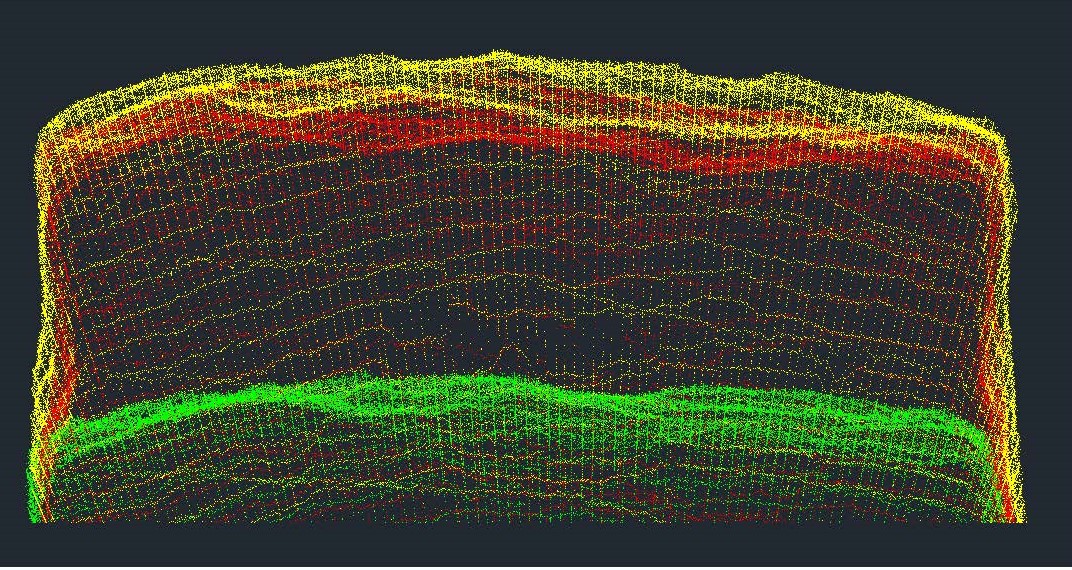

Project Year(s): 1

Project Description: The customer was interested in analyzing the difference in cut depth and scaling required between shots to track shot performance against blast changes made. We collected Quarryman 3D scan data of the stope pre-blast, post-blast, and post-scaling. Then Bethany analyzed the volumes and cut depths in Carlson AutoCAD. Additionally, we boretraked the holes in the stope to review drilling accuracy and its effects on the cut and scaling. Overall the customer came to the conclusion that they should adjust some drilling procedures to ensure the drilling was done in the proper angles, ensuring the best cut.

Winchester Technical Support

Carmeuse

Client: Carmeuse

Site: Clear Brook

Project Elements: Vibration Control, Shot Design

State and Country: Virginia, USA

Commodity: Limestone

Project Year(s): 2020 - 2021

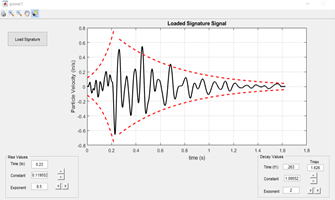

Project Description: Provide technical support for the blasting operation at Carmeuse, Winchester. The pit is around 300 feet from houses and a school, which poses significant flyrock and vibration concerns. Dyno Nobel was tasked with mitigating those risks with a primary focus on safe blast designs and performance optimization. Daily tasks include shot layouts, GPS hole locations, drone services, 3D profiling, and boretraking. For each blast, signature hole analysis was used to optimize timing, and the vibration and airblast were predicted at the nearest three seismographs. Airblast and vibration reports, a flyrock clearance map, and shot design details were provided to the customer before each shot. Thorough data and clear communication helped the client facilitate positive neighbor relations and ensured safe blast designs.

Proprietary Signature Hole Software & Analysis to Reduce Cast Shot Vibration

Midwest Coal Mine

Client: N/A

Site: Midwest Coal Mine

Project Elements: DynoConsult, Dyno42, SignaShot, DigiShot Plus

State and Country: Indiana, USA

Commodity: Coal

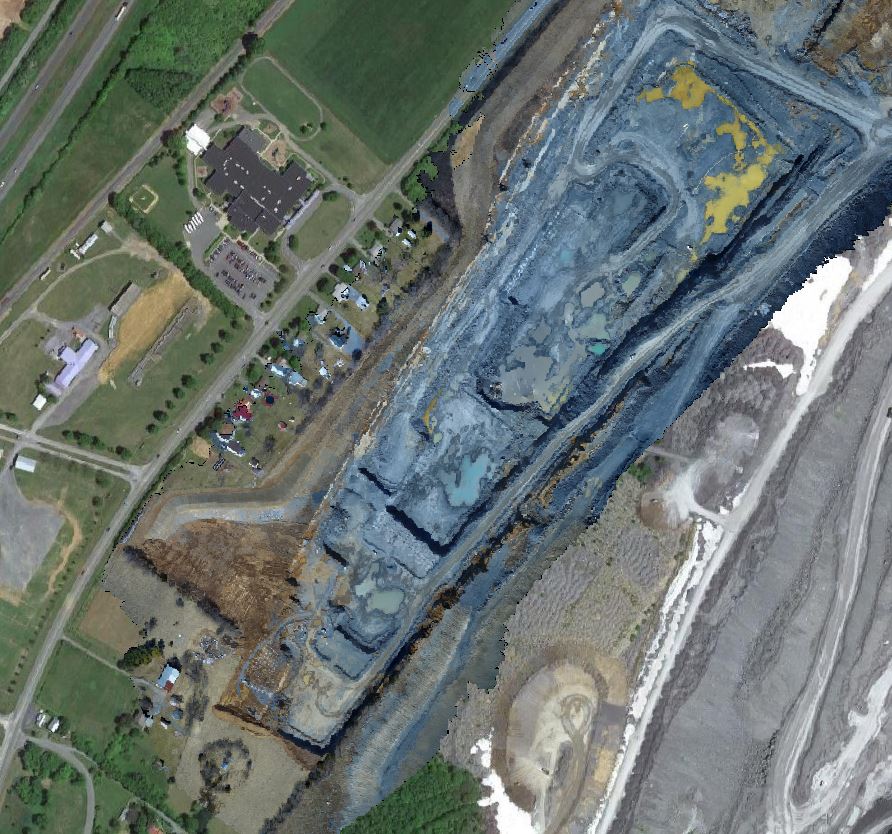

Project Year(s): 2020 - 2021

Project Description: A cast blasting coal mine located in Indiana had begun to deck cast blasts and were considering a switch to a smaller diameter hole as the mine progressed closer to two separate two inch per second (IPS) limit pipeline risers. The objective of the project was to stay under the two IPS limit while continuing cast blasting maintaining a single powder column, current hole diameter, efficient shot lengths, and mine’s desired timing ranges for performance. Dyno Nobel’s suite of signature hole analysis (SHA) tools, Dyno42 and SignaShot, were used in conjunction to identify and evaluate optimised timing schemes. Dyno42 analysed all desired timing sequences and shot length scenarios for the cast blast. The selected timing(s) was then simulated by SignaShot to provide a statistical range of the predicted PPV. This process would result in a selection of a timing scheme for areas of the mining cut. The project was successful as the vibration limits were not exceeded, all decking was eliminated, and the mine was able to maintain the status quo with regards to its cast blasting program. The postponement of transitioning to smaller diameter holes saved operational costs and efficiency. Additionally, the ‘business as usual’ cast performance and costs resulted in an agreement with the pipeline owner, who had been holding out in anticipation of the mine feeling financial pressure, to move the pipeline removing the vibration constraints on the pit. The results of each blast were also reviewed for adherence to SignaShot prediction and compared to a scaled distance calculated PPV to quantify the efficacy of the software.

Vibration Characterization and MSD Request

Wyoming Coal Producer

Client: Wyoming Coal Producer

Site: Powder River Basin

Project Elements: vibration monitoring, analysis, & recommendations

State and Country: Wyoming, USA

Commodity: Thermal Coal

Project Year: 2019, 2020

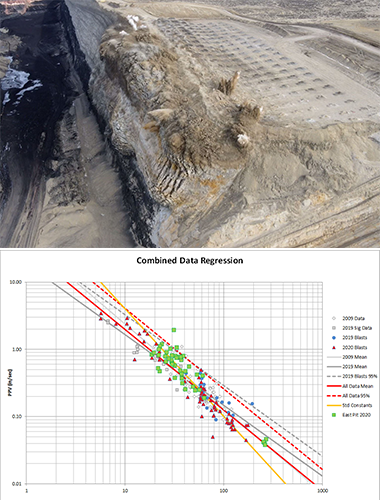

Project Description: A major thermal coal producer wanted to update their mining permit through a Modified Scaled Distance request to the WY-DEQ. A reduced Scaled Distance factor would allow additional flexibility in designing and loading blasts near protected structures without causing damage. DynoConsult had performed vibration monitoring years before at the mine, and it was felt that further work could build on that effort.

In collaboration with the mine, DynoConsult outlined a plan, performed a series of signature hole blasts, collected additional vibration data from regular mine blasts, and developed an updated characterization of the ground response. From this work, they showed the previous and current vibration data matched, and allowed definition of a new Modified Scaled Distance factor. They supported the mine in presenting the project, vibration data and results to the WY-DEQ. The result was approval of a Modified Scaled Distance factor for the mine.

Pipeline Project Pre-Job Analysis

Site:Planned Pipeline Route

Project Elements:DynoConsult

State and Country:Wisconsin, USA

Commodity:Pipeline / Natural Gas

Project Year(s):2021

Project Description: DynoConsult partnered with the Dyno Nobel pipeline division to assist a customer in quantifying and planning their drill and blast needs up a planned 42-mile pipeline re-routing project in Wisconsin. The pipeline operator had experienced budget deficits and missed deadlines in the past due to greater than anticipated blasting needs. To better understand scheduling and costs DynoConsult was contracted to provide projected lengths and locations along the planned path that would require trench and/or overburden blasting. Knowing this information prior to start of project provided several benefits to the client. This includes a more competitive and efficient procurement process, better budgeting, a more accurate project schedule which is important with work being scheduled around time constrained environmentally sensitive areas, and advance notice of blasting areas with elevated risk profiles.

To execute this pre-work survey Dyno Nobel traversed the entire planned length observing geology, topography, road cuts, and interviews to identify areas where blasting would be anticipated. The field notes were cross-referenced to geological maps, soil maps, and available borehole sampling to further define and confirm these areas. Once the locations and lengths were determined the volumes of rock removal were calculated and provided a degree of confidence rating with regards to the information. The project the engineer and field supervisor on the project provided information on anticipated needs including manpower, equipment, explosives, materials, and scheduling. A trench blast design that would match the desired excavation extents was created within this process as well.

The final report detailed areas where additional controls with regards to fly rock and blast induced vibration may be needed. Recommendations were given on what these controls could be and how to implement if used. The customer was pleased with the final report in assisting their planning process to control costs, set construction schedules, eliminate unplanned work, and having strategies provided to safely blast in areas of elevated risk.

Contact

Contact Us TODAY!