Capabilities

Our team of subject matter experts is responsible for maintaining and expanding this knowledge base as new technologies are achieved. Just as importantly, these experts generate standards and procedures which are then disseminated to the larger organization, ensuring a high level of service quality and consistency to customers. The degree to which drilling and blasting may impact the downstream processes of a mining operation is often underestimated. However, in order to maximize potential for customers, DynoConsult focuses on solutions which offer quantifiable and verifiable results to all aspects of the process.

Drill to Mill™

Drill to Mill delivers savings and optimizes outcomes across entire mining operations by assessing the full implications of changes to the drilling and blasting procedures. Our experts carry out Rapid Operations Diagnostics to accurately identify opportunities for improvements and then use their wide range of capabilities to implement changes that reduce costs and maximize profits at every stage of the operation.

Drill to Mill™ Capabilities

Scoping and Realignment

Evaluation of drilling, blasting, crushing, and milling using baseline audits and surveys, ore characterization, measurements, models/simulations, and material tracking

Analysis

Process analysis and identification of how variables interrelate

Process Optimization

Optimization of current processes for efficiency and effectiveness

Control of Processes

Gains sustained through continued process management

Safety & Compliance

A mine’s license to operate is dependent on its ability to meet and exceed safety and compliance obligations. Government and community scrutiny of these aspects consistently increases. Managers often fail to recognize the full financial benefit derived from taking proactive steps to address these moral and legal obligations. DynoConsult possesses multiple avenues to address these obligations, and to strategically limit costs while doing so.

General Offerings

Site Safety Audits

Our blasting experts perform detailed analyses of the drilling and blasting SOPs, practices, and conditions to minimize risk at an operation.

Site-Specific Drill & Blast Programs

Establish site-specific safety protocols for drill and blast crews, providing training and SOPs to “jump-start” a new operation, or get an existing operation back on track.

Explosive Product Training

New blasters may benefit from detailed instruction on best practices of the explosive products used at your site. Experienced blasters may have developed bad habits and require a refresher.

Regulatory Paperwork Tracking

Prevents basic paperwork violations by organizing and tracking reports and records. Our Electronic Shot Reporting (ESR) software provides automation ability.

Neighbor Relations

Experts stand ready to interface with community members either individually or at community meetings to present facts and science, improving knowledge and assisting in public hearing scenarios.

Expert Witness

Several of our experts have provided reliable support during litigation for a wide range of customers.

Remote Firing Capability

Introduction and training on our remote firing systems for both underground (BlastWeb) and surface (Commander) mines. Ensures your blasters always initiate from a safelocationwhile maintaining absolute control over the process.

Close-in Seismograph Vibration Monitoring

Use of seismographs installed near a surface or underground blast for the primary purpose of detecting misfires. Also provides indication of in-hole explosive performance.

EMP Misfire Detection

A groundbreaking new technology which monitors the EMP generated by an individual blasthole. This is an excellent way to detect misfires and can also be used to track accuracy of detonator delays.

Fume Measurement & Tracking

Capture the level of fume generation from individual blasts using both visual qualitative methods and UAV/terrestrial mounted sensors for quantitative measurement.

Fume Reduction Design

Ensures neighbor satisfaction by altering blast parameters and selection of optimal explosive product to reduce fumes such as NOx.

Groundwater Contamination Mitigation

Some mines operate in areas where groundwater quality is a major concern.DynoConsult provides recommendations to minimize nitrate leaching from explosives, among other possible pollutants.

Backbreak (Overbreak) Measurement and Tracking

Scanners and photographic analysis can be used in both surface and underground applications to determine extent of overbreak. Tracking this can be key to ensuring pit wall stability or roof control.

Overbreak Reduction Design

Advanced software programs and cutting-edge products can be used to reduce overbreak, improving safety and reducing costs related to pit wall repair and underground support installation.

Site Planning & Tracking

Generation of near-term blast planning.

- Site Production Planning - Generation of near-term blast planning mapped over the operation to balance requirements such as sales volumes, quality levels, etc.

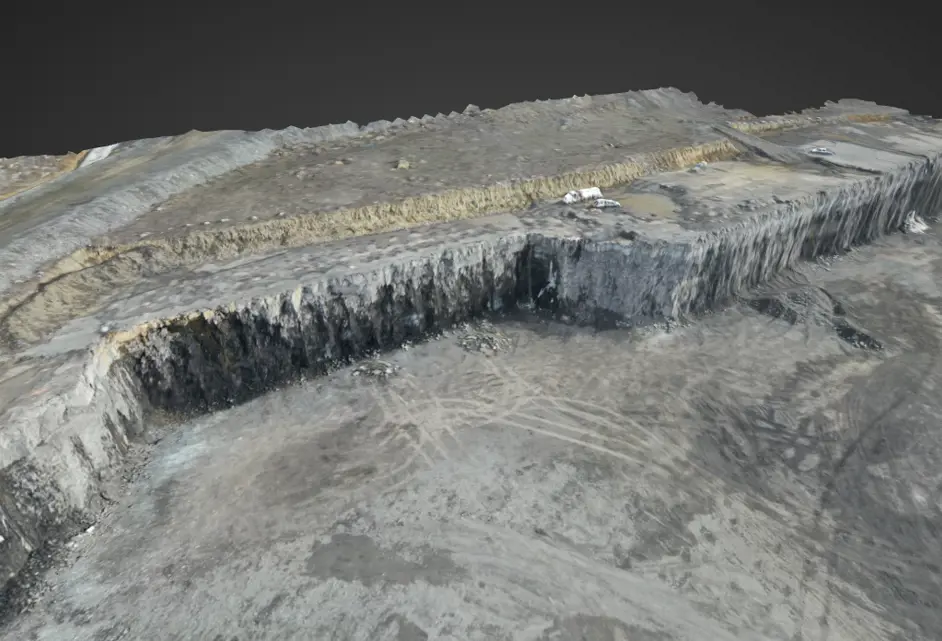

- 3-D Bench Modeling - FAA certified drone pilots to conduct aerial image capture for creation of a detailed 3-D model to be used in a large number of design applications.

- Stripping Ratio & Material Volume Calculation - Drone scans and models can be used to confirm stripping ratios and volumes of material moved each month.

- Blast Pattern Size & Shape Optimization - Design of blast patterns and bench height to maximize operational efficiency by limiting the number of equipment moves (production cycles) required and ensuring pit dimensions match equipment requirements.

- Blast Optimization Team (BOT) Training & Kickoff - Establishment and training of BOT team members and customer internal resources.

- Dashboard Creation - Creation of a site performance dashboard which:

- Establishes key operational metrics that indicate site performance

- Identify opportunities for operational improvements

- Sets and realizes measurable performance goals

- Provides corporations with an in-depth look at their portfolio of sites

- Equipment Fleet Tracking - DynoConsult has the capability to use telemetry systems installed on fleet equipment to track key performance statistics related to cycle times, throughput, etc. This can be integrated with possible existing systems the customer already has in place.

Production & Processing Optimization

Our team of experts help with.

- Time Studies - May be conducted using traditional personnel methods, or newer equipment tracking capabilities.

- Trend Analysis - Tracking performed to present impacts on digability, powder factor, shovel/loader dig rates, and many others.

- Drill Demand Minimization Analysis - Design to reduce drilling requirements and allow for possible fleet reduction. Achieved through examining viability of expanding patterns, smaller diameter holes, and pattern design efficiency among others. Reduces related costs such as bits, fuel, labor, etc.

- Muckpile Shape Optimization - 3-D terrain models captured from scanners are used to modify blast design parameters to ensure muckpile height and shape allows for the most efficient loading possible.

- Initiation System and Bulk Explosive Selection - Site analysis to determine if advanced products such as electronic detonators and gassed emulsion are economically justified for an operation.

- Explosive Distribution Planning - Assistance in designing ideal drilling and explosive distribution to reduce secondary blasting such as trim shots and boulders.

- Movement/Throw Predictive Modeling - DynoConsult has access to the proprietary GEM (Ground Earth Movement) numerical software to model the optimal blast design for a desired blast movement or throw.

- Floor & Road Grade Analysis - 3-D terrain models provide detailed contour mapping of pit floor and road irregularities, pinpointing areas that require work and highlighting blast design modifications which can improve grade going forward. This impact operational costs related to minimizing fuel burn, equipment maintenance and downtime, tire consumption, operator comfort, and improved cycle times (loading, hauling, dumping).

- Drill Hole Audits - Excellent blasting cannot compensate for poor drilling. High-level instrumentation such as survey grade GPS, borehole deviation measurement devices, and advanced software packages are used to ensure collar locations, angle holes, and drill drift are within acceptable limits.

- Dilution Reduction - Blast designs are configured to prevent intermingling of valuable ore and waste rock. The cost to transport and process nonviable material can be substantial.

- Hi-Speed Video Recording - Recording blasts at standard film speeds is widespread now. However, hi-speed video analysis can often give clear indication of where performance issues originate.

- Velocity of Detonation (VOD) Analysis - Recording and analyzing VOD often provides an indicator as to the underlying problems causing blast performance issues. DynoConsult operates both the MREL and Shottrack systems.

- Underground Heading & Stope Scans - Scans of advance headings or stopes can be used create 3-D models of underground production areas allowing several key analyses to be made:

- Face profiles

- Advance per round

- Scaling volume

- Overbreak

- Face Scan & Pattern Analysis - Combines scan and borehole survey data to provide detailed overlays for analysis of drilling accuracy.

- Underground Drone Flights - Capability allows close examination of the condition of areas which otherwise may be difficult or impossible to inspect. Can also be used to scan stopes for volume calculations.

Bulk Technology Implementation

Bulk Technology Implementation

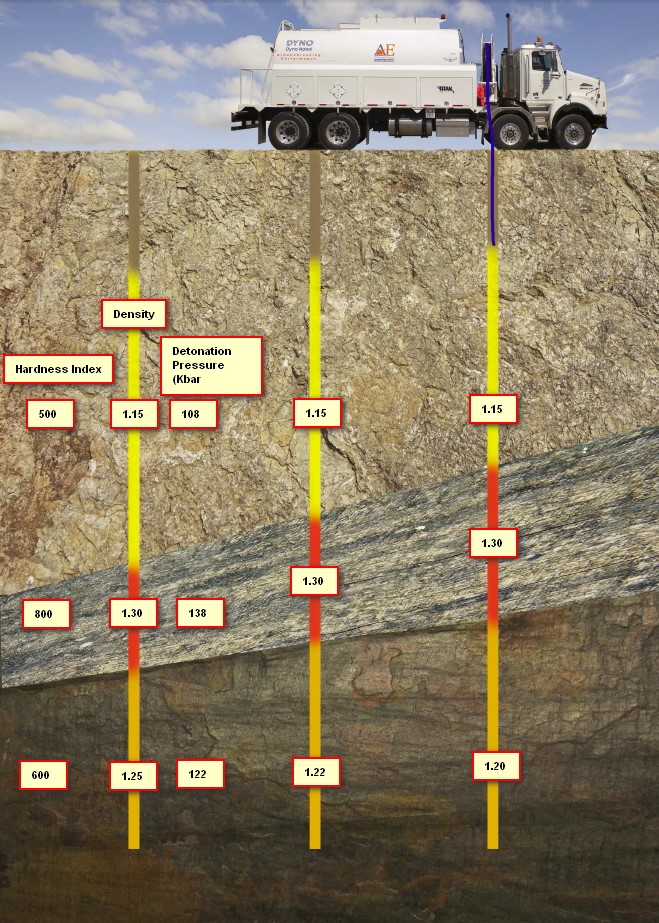

Dyno Nobel possesses the cutting-edge TITAN ΔΕ2 system, which uses chemical gassing to vary the density of bulk emulsion in response to geologic conditions and blast design factors. This system utilizes data obtained via sensors installed on various manufacturer smart drill packages, including GPS data related to borehole location, down pressure, rotation speed, engine RPMs, etc. This data is uploaded to the ΔΕ2 Preload application allowing the customer to build loading profiles to match the energy requirements of the geology being blasted. These loading profiles may be generated automatically using algorithms which incorporate the smart drill data, resulting in each blasthole being loaded with a unique explosive profile. DynoConsult can provide support in implementing this technology at your operations, using the following approaches.

- Smart Drill Integration – Smart Drills are becoming more prevalent, but often the data is not used to its full potential. DynoConsult can assist in capture and integration of this data into the drill & blast process.

- Loading Profile Automation – Smart drill data can be combined with algorithms to generate customized loading profiles for individual blastholes. Blasting crews simply pull up to the blasthole, and push a confirmation button to begin loading.

Instrumentation & Software

Instrumentation

Accelerometers

Pressure sensors

Electromagnetic pulse recorder

BoreTrak and Devico borehole survey systems

Survey Grade Trimble GPS Phantom, Mavic, & Inspire series UAVs

Terrestrial scanners such as the Quarryman Seismographs

MREL & ShotTrack VOD recorders Hi-speed cameras

Blast movement sensors

Accelerometers

Pressure sensors

Electromagnetic pulse recorder

BoreTrak and Devico borehole survey systems

Survey Grade Trimble GPS Phantom, Mavic, & Inspire series UAVs

Terrestrial scanners such as the Quarryman Seismographs

MREL & ShotTrack VOD recorders Hi-speed cameras

Blast movement sensors

Software

|

Carlson SurvCad |

Pix4d ViewShot 3d Electronic Shot Reporting Dyno42 Seismograph Software Alphablast GEM Sirovision Motion Metrics O-pit Blast Strayos DynoMobile Data Miner |

Specialty Projects

Often, a customer has a specific goal in mind which requires creation of a completely new project design. DynoConsult is experienced in construction of these specialized projects, whether it be as small as blasting 6 inches of rock next to a critical structure, or large scale mine blasts.

- Close-in blasting

- Void collapse blasting

- Equipment rescue

- Blasting next to failures

- Custom built sensors to customer specification

- And much more